Unveiling a Thorough Selection of Resilient Undercarriage Parts for Heavy Machinery

Unveiling a Thorough Selection of Resilient Undercarriage Parts for Heavy Machinery

Blog Article

Make Best Use Of Performance With Resilient Undercarriage Parts

In the world of hefty equipment and tools, the function of undercarriage components is critical in guaranteeing optimum efficiency and longevity. The efficiency and effectiveness of these components can substantially affect the overall procedure of equipment, making the selection of long lasting undercarriage components a vital decision for supervisors and drivers alike. By exploring the intricate connection between resilience and performance in undercarriage parts, a deeper understanding of the subject emerges, clarifying the pivotal variables that drive functional success. As we navigate through the complexities of undercarriage longevity, part, and maintenance option, a detailed exploration awaits to reveal the essential approaches for achieving peak performance in heavy-duty applications.

Benefits of Making Use Of Sturdy Undercarriage Parts

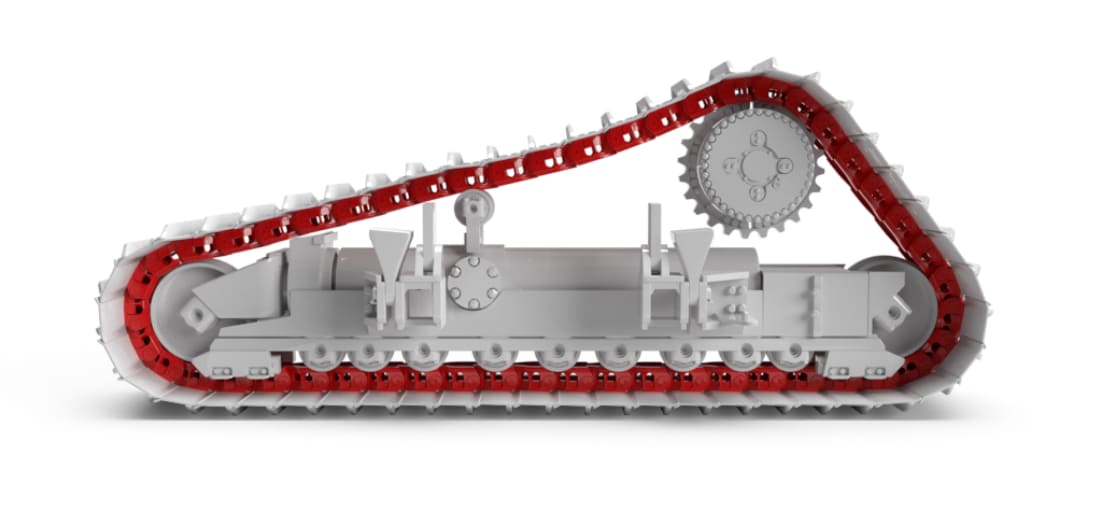

Utilizing durable undercarriage components not only improves the longevity of hefty machinery but also decreases upkeep costs considerably. By purchasing high-quality undercarriage elements, such as tracks, gears, idlers, and rollers, devices operators can experience increased uptime and boosted general performance.

Furthermore, the longevity of heavy equipment is directly connected to the high quality of its undercarriage components. Sturdy elements can endure the roughness of requiring applications, guaranteeing that the equipment continues to be operational for extended durations. Because of this, operators can stay clear of costly downtime and maintenance expenditures, inevitably making the most of the return on financial investment for their machinery.

Elements Affecting Undercarriage Toughness

The longevity of undercarriage parts in hefty equipment is affected by numerous essential elements that directly influence performance and longevity. Among the key aspects impacting undercarriage toughness is the high quality of materials utilized in production. Premium materials, such as solidified steel, are vital for withstanding the severe problems and heavy tons that undercarriage components are subjected to. Proper maintenance methods also play a critical function in determining the life expectancy of undercarriage components. Normal inspections, lubrication, and timely substitute of worn-out parts can significantly prolong the toughness of the undercarriage.

Furthermore, ecological factors can have a considerable influence on the durability of undercarriage parts. Direct exposure to rough materials, severe temperature levels, and rough working conditions can accelerate wear and tear on undercarriage elements. Selecting undercarriage components that are particularly created to withstand these environmental obstacles is vital for ensuring resilience.

In addition, the style and design of undercarriage components have a direct impact on their resilience. Components that are made to disperse loads equally, lower friction, and minimize stress and anxiety concentrations are more likely to have a much longer lifespan - undercarriage parts. By thinking about these critical variables, equipment operators can optimize the resilience and efficiency of their undercarriage components

Maintenance Tips for Prolonging Undercarriage Life

Executing routine maintenance regimens is crucial for expanding the lifespan of undercarriage components in hefty equipment. To prolong the undercarriage life, it is critical to regularly check for deterioration. Routinely look for absent or loose screws, damaged rollers, or misaligned tracks, as these problems can intensify and trigger additional damages if not resolved immediately. In addition, guarantee that the undercarriage is effectively oiled according to producer guidelines to lower rubbing and prevent premature wear.

One more vital upkeep tip is to keep the undercarriage tidy from dirt, rocks, and debris. Buildup in the undercarriage can increase wear and corrosion, bring about pricey repair services. Washing the undercarriage after procedure in extreme problems is advised to avoid these issues.

Last but not least, tracking and recording maintenance tasks can aid in producing a positive upkeep schedule. Keeping thorough records of substitutes, fixings, and evaluations can offer valuable insights into the undercarriage's condition and efficiency with time, aiding in forecasting and stopping prospective failures. By adhering navigate to this site to these maintenance suggestions faithfully, operators can considerably raise the longevity and performance of undercarriage components in heavy machinery.

Choosing the Right Undercarriage Elements

Choosing suitable undercarriage parts is vital for making the most of the efficiency and durability of heavy machinery. When it comes to picking the best undercarriage parts, there are several factors to take into consideration.

Deciding for trustworthy brands understood for producing high-performance and durable undercarriage components can considerably affect the overall performance and longevity of the machinery. By very carefully picking the best undercarriage parts, devices proprietors can improve efficiency, lower downtime, and expand the life-span of their hefty equipment.

Study: Enhanced Performance With Sturdy Components

Incorporating long lasting undercarriage components has demonstrated substantial improvements in equipment performance. One case research study entailed a construction company that updated its excavator's undercarriage elements to a lot more durable choices. The business observed a notable decrease in downtime due to undercarriage upkeep, resulting in boosted efficiency and price savings. The sturdy components endured severe working problems, decreasing wear and tear considerably.

In another circumstances, a mining operation replaced the undercarriage parts of its excavator with premium, long lasting choices. This button led to an impressive improvement in the visite site bulldozer's ability to move and total efficiency. The maker might browse challenging surfaces a lot more efficiently, leading to enhanced functional performance and lowered gas consumption.

Furthermore, a logging firm spent in sturdy undercarriage parts for its forestry equipment. These situation research studies emphasize the tangible benefits of making use of long lasting undercarriage parts in maximizing equipment efficiency and long life.

Conclusion

In verdict, using sturdy undercarriage parts can considerably boost performance and long life of heavy machinery. Instance researches have revealed that spending in durable undercarriage components can lead to enhanced general efficiency and efficiency in numerous industries.

The efficiency and effectiveness of these components can significantly influence the overall operation of machinery, making the selection of long lasting undercarriage parts an important choice for operators and managers alike.Integrating durable undercarriage components has demonstrated significant improvements in equipment efficiency. These Visit Website case studies emphasize the concrete advantages of making use of durable undercarriage parts in optimizing machinery efficiency and longevity.

In conclusion, using long lasting undercarriage components can considerably enhance efficiency and long life of heavy machinery (undercarriage parts). Situation researches have actually shown that spending in long lasting undercarriage components can lead to improved general performance and productivity in various industries

Report this page